Freres Lumber’s Mass Ply Panel is an affordable mass timber product that is gaining worldwide acceptance as a safe, high performance, and environmentally sound building material. This veneer-based product can be produced up to 12-feet wide, 48-feet long, and 12-inches thick, allowing engineers, architects, and builders more design and building freedom.

An Efficient Use of Our Natural Resource

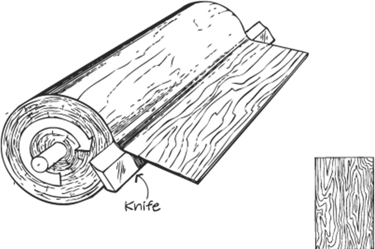

As opposed to lumber-based products, mass timber has the advantage of being produced from an 1/8-inch thick sheet of wood that has been peeled off a log, rather than a square piece of lumber processed from a log. This allows for more wood fiber to be recovered. Also, smaller trees can be processed that otherwise couldn’t be used in a structural application, thus, creating a higher value product from low-impact harvesting methods, such as thinning.

The efficiencies of Mass Ply also show up during the drying process.

Due to the naturally thin composition of veneer, the sheets can be dried in as little as 6 minutes, whereas lumber being thicker takes significantly longer. Also, there is less defect found in veneer than in lumber, which can warp, twist, or cup during drying and must be rejected. In contrast, sheets of veneer flatten out and can be used in the final product.

These factors, when compared to similar products, give Mass Ply an advantage by recovering more usable wood from every log, requiring less energy to dry, and minimizing the amount of wasted material. This efficient use of wood is just one of the factors that makes Mass Ply a more affordable product.

The Mass Ply Production Process

Mass Ply is a composite lumber panel produced through an automated process which stacks and glues individual layers or lamellas together to form one large format panel. This is all done with robotics to make the process predictable, safe, and streamlined. After the panel is formed it moves to a 24-inch press to be compressed and cured. The 24-inch press allows for multiple panels to be manufactured at a time. As an example, a press load can consist of (4) 6-inch panels, or (6) 4-inch panels, or (12) 2-inch panels. That is, respectively, about 18,430 ft2, 27,650 ft2, and 36,860 ft2 of floor area per day at the current production rate. At these production rates Mass Ply can meet the contractors’ construction time frames faster at an affordable price.

Cost Savings Start with the Design

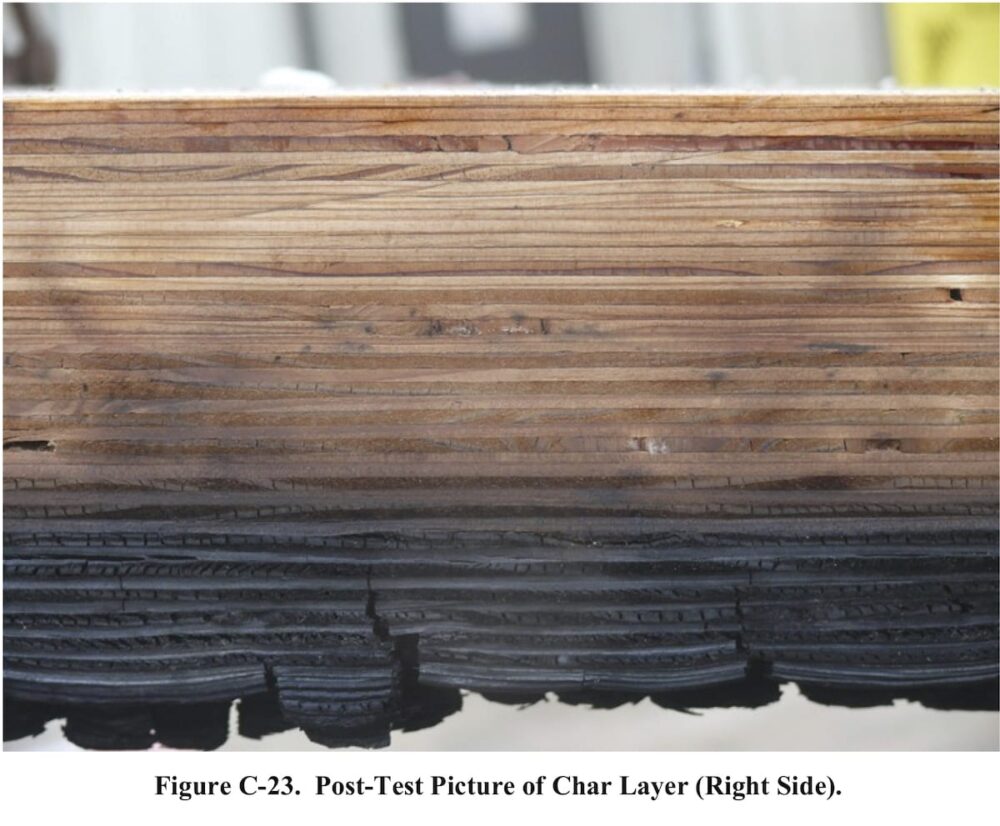

Save more by leveraging Mass Ply’s performance. Mass timber in general has outstanding fire and structural performance levels and can be a direct substitute for conventional concrete floor systems. Mass Ply is no exception to this, its unique thickness options allow the designer to refine the design for even more cost savings.

The thicknesses range from 2-inches to 12-inches at 1-inch increments. To compare, a typical mass timber floor system requires a 5-ply CLT panel at 6-7/8-inches thick, whereas a 6-inch Mass Ply panel can be a direct substitute and would result in 15% less wood—a cost that is proportionately tied to the final cost of the product. Now, shrink those spans a little over 2-feet and use 5-inch Mass Ply and that would equate to a 38% savings in wood. As you can see, there are substantial savings to be had by effectively using Mass Ply’s various thicknesses.

Thinner sections give the designer an opportunity to rethink the different applications typically found in mass timber. You can conceivably use 2-inch walls in residential and 2 or 3-inch floor panels with joist spaced at 7.5 and 10-feet respectively. Perhaps the 1-inch thick, 4-feet wide and a length only limited by trucking structural panel can be used creatively on the next job.

There are many products that are coming out of the development of Mass Ply. Joist pieces that can be used in floors or walls, 24-inch thick columns, 24-inch thick plank-oriented beams, 6-feet deep beams on edge, even rim boards and crane mats. All these products provide the luxury of prefabrication with the precision that comes from computer numerical control (CNC) cuts. This presents a huge opportunity to create new, possibly, revolutionary building systems for commercial and residential applications from creative people willing to experiment with a new path in construction.

Making the Turn to a More Affordable Mass Timber Product

When it comes to building, I would urge everyone to consider a wood-based product. Wood is the most environmentally responsible building material available. There are many mid-rise buildings that are great examples of how mass timber construction can be a better financial investment in building material than concrete and steel.

Each mass timber product brings with it its own unique value; it’s just a matter of researching options and understanding how each can be incorporated into your next project. As a veneer-based product, Mass Ply offers many ways to reduce the overall cost and its high structural and fire performance, coupled with its variable thickness options, gives it the ability to be fine-tuned for your specific needs; therefore, reducing your cost per square foot.

Subscribe

We’ll send you a notification when a new story has been posted. It’s the easiest way to stay in the know.