Freres Lumber’s Mass Ply Panels have been put through rigorous testing, gaining several engineered wood certifications and proving to be a high preforming material for multi-story construction. So, what’s next for Mass Ply?

Beams and Columns

We are currently certified for laminated veneer lumber (LVL) and Mass Ply. These two certifications are the foundation for many products to come.

The next round of testing will be for deep beams on edge, with proposed testing for beams up to 6-feet deep by 12-inches wide, with possible spans of over 100 feet! With Mass Ply’s minimal shrinkage and swelling, we should be able to splice these beams together with a steel knife plate and screws without concern of cracking (as shown below).

Screw technology has boomed alongside mass timber making these knife plates easier to install and stronger. These screws, as opposed to bolts, are smaller in diameter and a tighter fit and, thus, can disperse the load better to create a stronger connection while minimizing cracking.

Soon after deep beams on edge, we will be working on a certification that will give us the ability to produce beams (in plank orientation) and columns up to 24-inches thick, which will be processed in a highly automated way that is not common within the industry. The processing line will be able to cut diagonals for structural and architectural reasons. With steel knife plates and the processing line we could potentially replace structures as shown below with wood.

Different Grades of LVL and Mass Ply to Support a Variety of Applications

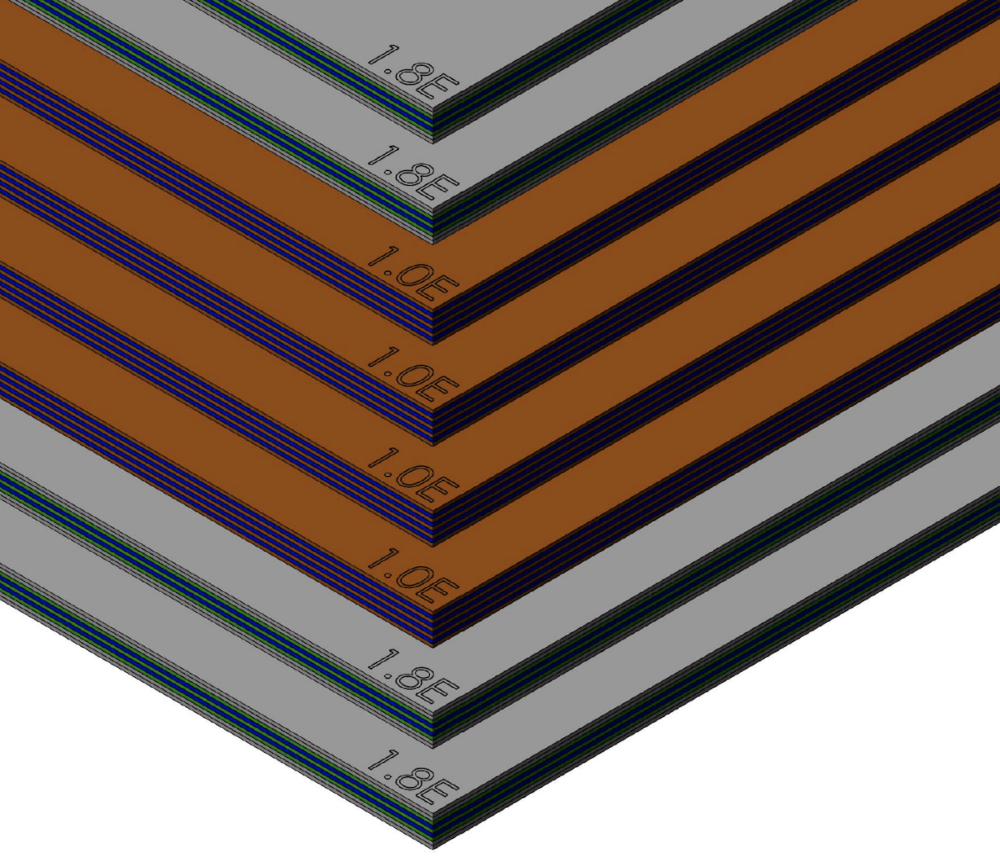

As of today, we have three different grades of LVL (1.0E, 1.55E, 1.6E) and one Mass Ply (1.6E). LVL is the building block of Mass Ply. We can take these different grades to build up the Mass Ply.This method is common with glulam beams. The higher quality, more expensive wood to be utilized on the outside of the product, and places the lower quality, less expensive wood at the center of the product, resulting in a product with similar structural properties, but at a much lower production cost.

Currently, Freres Lumber’s Mass Ply is all 1.6E grade, which uses G1, the highest grade of veneer. This means we can do the same thing as glulam by putting the highest grade on the outside of the beam and the lower grade can be used in the middle (see image below). This increases the affordability of our mass timber product without sacrificing its performance.

Raising the Potential of Mass Ply

Our plan is to maximize Mass Ply’s structural concept to its full potential. We will soon be testing a more traditional LVL product that will be a 2.0E (all the veneers running lengthwise, i.e. no cross plies). This can be used as the outside layers of Mass Ply, resulting in a stiffer, stronger panel. To build up the strength across the width of the panel we can place the LVL crosswise in the layup (currently lamellas are laid longwise over the length of the panel). This will provide a better two-way span that is able to eliminate the beams and create a panel that spans four columns.

New Applications to Explore

There are many more Mass Ply design possibilities to discover. We see efficiency and versatility in the different layup options and the beam and column processing lines. While there’s a lot to look forward to with Mass Ply, the current LVL and Mass Ply product capabilities already offer a viable economic, and environmental solution to many building projects.

Subscribe

We’ll send you a notification when a new story has been posted. It’s the easiest way to stay in the know.