December 7, 2020

The Freres environmental product declaration (EPD) is the pot of gold at the end of our eco-friendly rainbow. For over a year now, the Freres team has been working on a set of reports to tally the benefits of Mass Ply Panels . We are taking a closer look at what the process entails to get an environmental product declaration and how the wood products industry can benefit from such a report.

Creating a product EPD is a little more involved than just looking up how “green” is wood. In terms of the big idea, creating an EPD is a two-step process. First, there is publishing a life cycle assessment (LCA) of your product. This is followed by publishing the EPD report from the LCA.

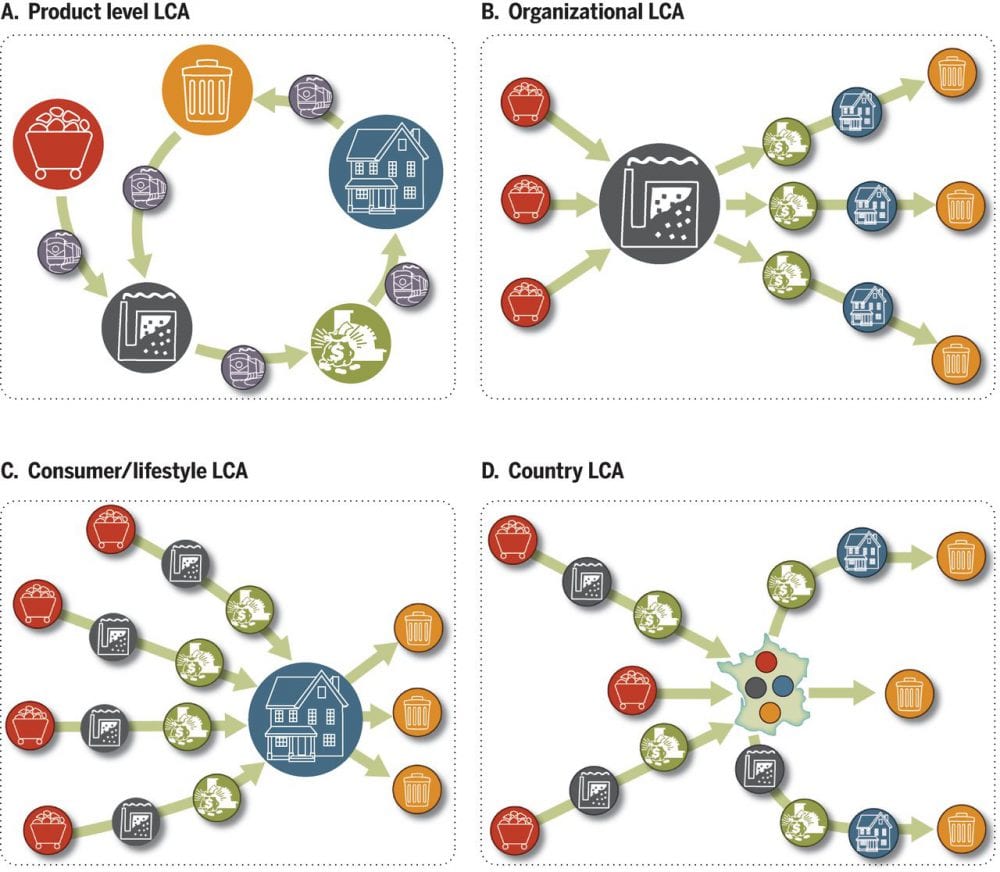

Creating an LCA is no small task. An LCA report tracks all the material, energy, and labor that goes into making a product. Also, LCA reports track all the work and waste after the product is made. For more about these reports check out our LCA blog post.

An illustration from the journal Science showing the variety of applications for LCAs.

An LCA is a complex report with many tables, numbers, and ideas about the impact of Mass Ply. For someone using Mass Ply and tracking the impact on nature, handing them the LCA would be like handing them a textbook. Sure, the textbook can probably answer their questions. But unless they already know the book, they will have a tough time finding the data they need. This is where the EPD steps in.

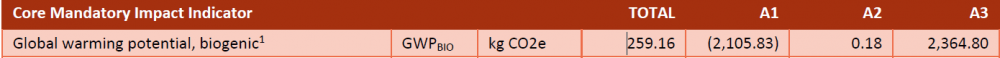

The EPD is to an LCA as CliffsNotes are to a book and it is written using an LCA. The EPD recaps the most important data from an LCA into a concise paper. It includes things such as global warming potential, power use, pollution, and the amount of carbon that Mass Ply stores during its life. There are many other measures that are included in this paper.

This example EPD table shows the carbon pulled from the atmosphere during tree growth (A1) and the amount of carbon it takes to move the material (A2) create the product (A3)”

Until now, our reports have only measured the impact of Mass Ply before it leaves the company. The report is limited because the uses of Mass Ply are vast after it leaves the plant. Some of the many uses of Mass Ply include: walls, floors, roofs, protective surfaces, industrial use, and rail ties.

It is hard to create one report that summarizes the impact of Mass Ply for so many different uses. Product EPD reports are treated like Legos in this case. Each Lego builds on each other to make a more complex structure.

Chemeketa Community College’s new Agriculture Complex used Mass Ply for construction of the roof.

Let’s say there is an architect who wants to create an LCA for a building. The architect needs to know the environmental impact of all the material that is in the building. This is where the product EPD becomes useful. The product EPD reports feed into the building LCA piece by piece to make the groundwork of the report. By adding construction methods and running costs for a building, a new LCA begins to take shape. That’s right, LCA reports create EPD reports which create more LCA reports!

The EPD report is key for Freres to make Mass Ply widely offered on the market of eco-friendly goods. Making it easier to include Mass Ply into a project means one more reason to consider mass timber as a sound alternative to traditional building materials. For Mass Ply, the sky’s the limit with the new EPD report (or at least as tall as the building code will allow).

Cody Beairsto, Quality Control Technician

Subscribe

We’ll send you a notification when a new story has been posted. It’s the easiest way to stay in the know.