This last May I had the fortunate opportunity to travel as a member of the Pacific Lumber Inspection Bureau (PLIB) Board of Directors and Members to Austria and Germany. Many are not aware that the PLIB certifies member mills in the US, Canada, and Europe. Their service as a grading and certification bureau is important to ensure that US lumber quality standards are met or exceeded for products coming from member mills, no matter where they are located.

The purpose of the trip was ostensibly for a regular annual meeting, but it was also an opportunity for outreach to European member mills, who are important to the PLIB, and to provide North American mill operators a chance to see European manufacturing methods and technologies. It was also a bonus that LIGNA, which is the largest wood products conference in the world, coincided with the end of our visit and tour.

It is tempting to describe every step of this once-in-a-lifetime visit, and it would be easy to dwell on some of the amazing sights along our travels starting in Zell am Ziller, Austria and Hannover, Germany at LIGNA. If you would like a detailed description of the trip, the PLIB has done a great job of describing our journey. I would like to focus on some of the items that struck me most during our visit.

Timber Management

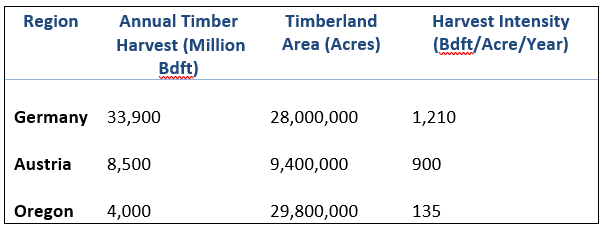

Europe has been managing their timber for generations, many more than we have in North America. In a nutshell, they intensively manage their forests. Germany, for instance, has a similar timberland base as Oregon but harvests 8-9 times more timber. Austria is less productive due largely to the mountain terrain but is still 4 times more productive than Oregon forests.

It is important to note that both Germany and Austria manage forestland for multiple uses, whether that is for recreation, environmental health, or for timber harvest; and these uses do not conflict but can support each other.

To put the timber harvest volume in perspective, the BLM estimates that 13 local jobs are created for every million board feet of timber harvested, and about $647,000 of employment income. With delivered log cost in Europe of about $120/cubic meter, which equates to less than $300/ thousand board ft, it is no wonder that mills in the Pacific Northwest purchasing logs for $750-900 per thousand board ft have difficulty competing against imports. Germany created the concept of sustainability in the 1700’s and has been applying it successfully for more than 200 years. We would do well to consider emulating their model.

Mills are Part of Communities

It struck me that the mills, their infrastructure and many of their products were integrated into the local communities. Many of the mills we visited operated biomass cogeneration facilities that provide electricity to the local grid. Sawdust residuals from mill operations were converted to pellets and many of the residents relied on those pellets to heat their homes in the winter.

With concerns about reliance on Russian natural gas due to the conflict in Ukraine, you can imagine that providing local electricity and heat is more than a question of convenience and is ultimately an issue of national security.

My Thanks

I can’t say enough about the hospitality provided by the European member mills, or the citizenry of the towns and cities we visited. In particular I would like to thank Binderholz Group for sharing their facilities for our board meetings and letting us tour their sawmill and glulam facilities.

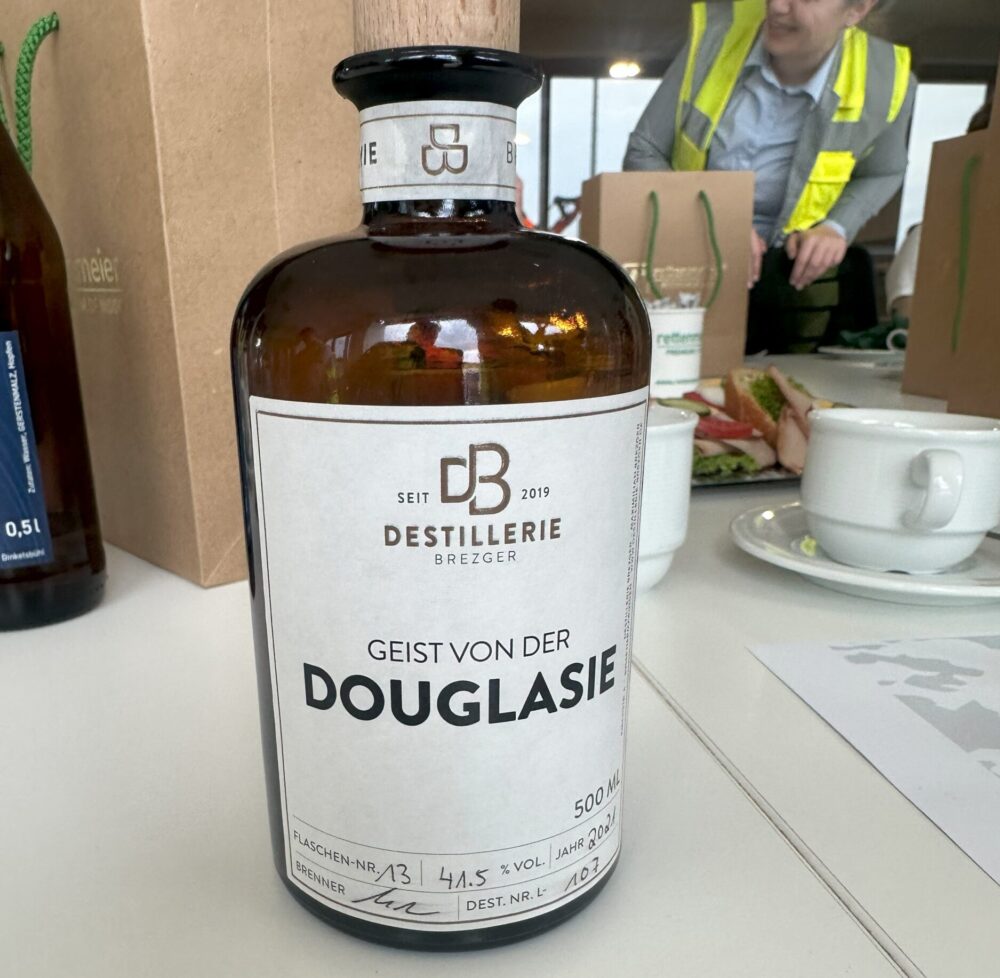

Rettenmeier hosted our group in their Wilburgstetten mill, and not only were we able to see one of the most modern mills in Europe, but we were treated with Douglas Fir Schnaps. Mercer’s mill in Saalburg-Ebersdorf was a marvel as well. All of these mills operated log yards that were completely different from what you would see in the states, using sophisticated sorting systems to improve the efficiency of their operations.

This was a great opportunity to meet European PLIB staff, and I was struck by the knowledge and experience of each staff member who covered large territories and interfaced directly with European member mills. The PLIB not only has a deep bench, but can provide a wide range of services from lumber grading to product certifications in engineered wood products, packaging, and even consulting services.

Lastly, this trip was my last stint as the Board Chair for the PLIB and I want to say thanks to the board for the opportunity to serve. I want to extend my best wishes to Sam Sanders from RSG, the new Board Chair and my gratitude to the staff for their support.

Subscribe

We’ll send you a notification when a new story has been posted. It’s the easiest way to stay in the know.