August 3, 2020

Freres’ newly released Life Cycle Assessment (LCA) for Mass Ply Panels (Mass Ply), has shown exciting results regarding the environmental sustainability of Mass Ply. Before diving into these results, it may be helpful to review what an LCA is.

What is an LCA?

LCA represents a method of evaluating supply chains. It evaluates systems that consume resources and the production of products from these systems. An easy way to look at an LCA is like a massive effort in accounting, but focusing on more than just money. There are four simple steps to the LCA process:

- Define the scope and goals of the LCA.

- Take a “Life Cycle Inventory” (LCI) of your process.

- Make a “Life Cycle Impact Assessment” (LCIA) of your processing using the completed LCI.

- Interpret the results and make improvement assessments.

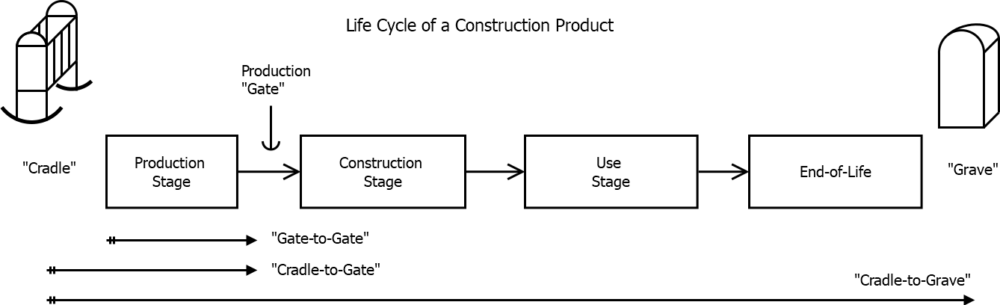

A Life Cycle Assessment varies in size, scope, and intensity. A lower intensity, conceptual LCA will have very basic comparisons and no direct data about the process. A higher intensity, detailed LCA will have in-depth data collection and highly specific process information. The scope of an LCA can encompass several different lenses, which commonly include:

- “cradle-to-gate”

- “cradle-to-grave”

- “gate-to-gate”

This is a visualization of the “life cycle” on a construction product. In this example, “cradle-to-gate” encompasses all the resources used to create a product (e.g. cradle) to the time said product leaves the production “gate.”

Using Mass Ply as an example, the cradle begins at the forest with the timber and it ends when the Mass Ply ships from the plant to the customer. All factors in between those steps influence the goals and impact of the LCA.

What does an LCA measure?

Once the scope and goals of the study are established, a Life Cycle Inventory may be conducted. The LCI looks at every “stage” of the life of the product based on its scope and evaluates every possible input. For Mass Ply, a “cradle-to-gate” study might include:

- Timber volume and weight.

- Glue volumes and weight.

- Transportation costs and materials.

- Energy used for manufacturing the product and everything that goes into it.

- Emissions produced during each step of the process.

Based on the inputs, the outputs are then accounted for. This would include the products, byproducts, and any waste.

How does an LCA use those measurements?

The Life Cycle Impact Assessment is where the accounting turns into real analysis. One impact factor in an LCIA is the global warming potential. From cradle-to-gate, Mass Ply contributes net zero to global warming measured in terms of “equivalent mass of carbon dioxide.” This means that starting at installation, an Mass Ply panel has yet to contribute to the warming of the atmosphere.

We can think of Mass Ply as a blank canvas regarding the environment. After installation, its impact on global warming depends on its end use and what the end of its useful life looks like. With proper design and consideration, structural Mass Ply can be used to retain its environmental benefit and still act as an effective structural product.

What comes after an LCA?

Using the LCA, Freres’ next step is to obtain an Environmental Product Declaration (EPD). An EPD communicates the takeaways of an LCA, and will also provide a basis of comparison with products that have similar uses. This will help customers to make smart decisions regarding their next project and highlight all there is to gain from using a product like Mass Ply.

Cody Beairsto

Subscribe

We’ll send you a notification when a new story has been posted. It’s the easiest way to stay in the know.