November 18, 2019

As some of you may know we are working on installing a beam and column processing line in the next couple of months. This is pretty exciting as we will be able to produce beams and columns up to 24” thick. The processing line will allow Freres Lumber to supply all the structural materials up an 18-story building in Oregon and Washington. The IBC 2021 will allow for 18-story wood buildings and soon this will be allowed in all the other states as well. Closer to home, the processing line will provide materials for an upcoming Mass Ply breezeway at our facility.

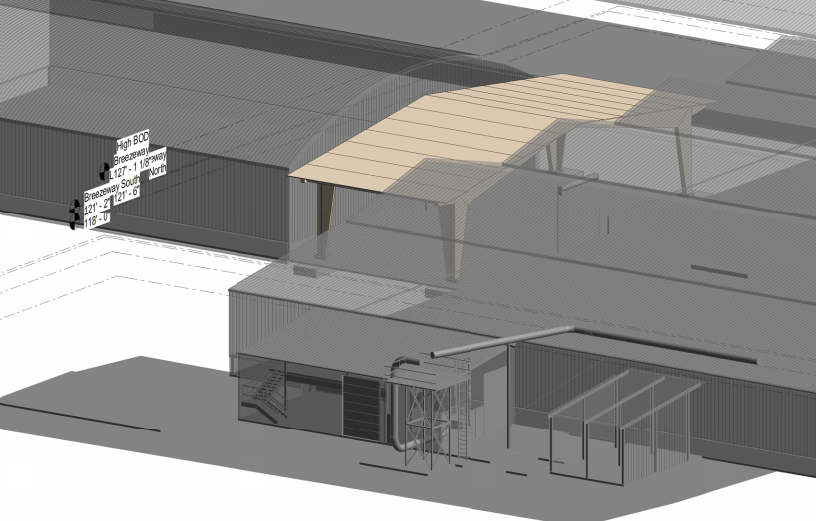

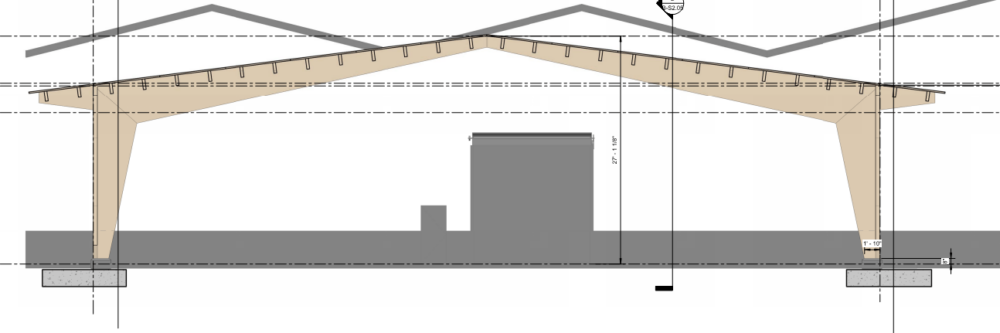

A project that Freres is working on for their own facility is a 93’6” x 43’ Mass Ply breezeway connecting buildings at the plywood plant, Plant 3 in Mill City. The upcoming breezeway project is an example of what can be accomplished with Mass Ply beams and columns. This exciting project will have a wooden frame that is spanning 93’6”! Typically, this is something that can only be done with steel, since in the past wood was usually too dimensionally unstable. It could twist or warp, shrink or swell. However, using Mass Ply, the laminated wood columns are extremely stable and universally strong, offering new possibilities for designers and architects.

Advantages of Mass Ply

An industrial structure like this would typically be thought of a steel or Pre-engineered Metal Building (PEMB) and nothing else. However, using Mass Ply in industrial buildings can make these otherwise unattractive structures beautiful. It can even create a more desirable working environment for employees. A wooden structure can also give the building a sustainability advantage by storing the carbon that was sequestered by the trees that were harvested to make Mass Ply.

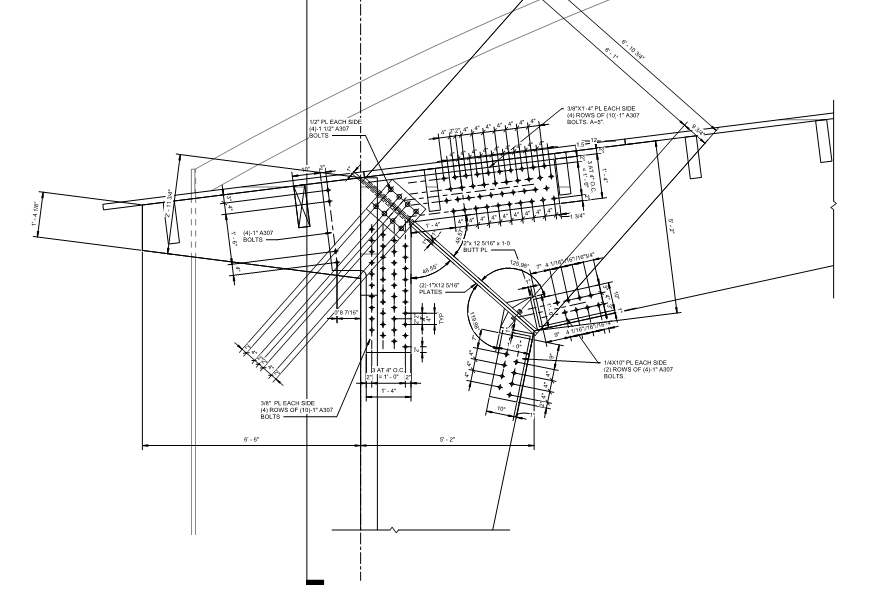

Of course, this is all new and there will be a learning curve to overcome. One of the difficulties of a wood structure like this is the connections. As you can see in the image above, the connections can be complex and time-intensive to fabricate. However, I’m sure as wood structures continue to play a bigger role in today’s buildings, novel solutions will emerge.

As wood, pound for pound, is stronger than steel it still takes a lot of wood to make spans this far. In the long span direction, the columns and beams are going to be 12” thick! Where in the short span direction at ~35’ will only require 6” thick members. It will be an impressive structure to see that also has the potential to change the outlook for future industrial buildings. A special thanks John Bradford at Crow Engineering for designing this structure. We will be sure to update you on this exciting structure as we begin to build it.

Austin Basl, Structural Engineer

Subscribe

We’ll send you a notification when a new story has been posted. It’s the easiest way to stay in the know.