Wood decay (rot) is a common concern, especially in Oregon. It is well known that wood must be protected before, during and after construction. We frequently communicate with building professionals who need to prevent decay in their projects. With so much research on the topic, we have studied the durability of Freres Lumber products, as well as how they age. When asking what causes wood rot, the answer points to five conditions or ingredients that must occur at the same time.

-

Source of infection

When it comes to sources of infection, fungi are the only agents of wood decay. There are a few ways that disease and infection can spread. Decayed wood may spread disease to sound, healthy wood through normal fungi growth. It may also spread directly from soil to wood. The organic matter in soil is home to growing fungal organisms that can infect the wood upon contact. Sometimes airborne fungi is the culprit, as it is spread through the air to sound wood.

Wooden Boards Image by SharieProductions via Flickr

-

Suitable substrate

After a source of infection, fungi needs a suitable substrate to grow. In this case, it is wood tissue that provides the suitable food. The cellulose, lignin, and other components of the cell walls all fuel fungi growth. There are certain wood species that are the exception, such as cedar, redwood or white oak. These species are durable and contain substances that are toxic to fungi. It is also possible to eliminate the fungi’s food supply by applying treatments to the wood. Oil-borne and water-borne chemicals are the two basic types of wood preservative. These treatments are typically toxic for fungi but harmless for humans and animals.

Wet Wood Image by Johnny Let via Flickr

-

Moisture content

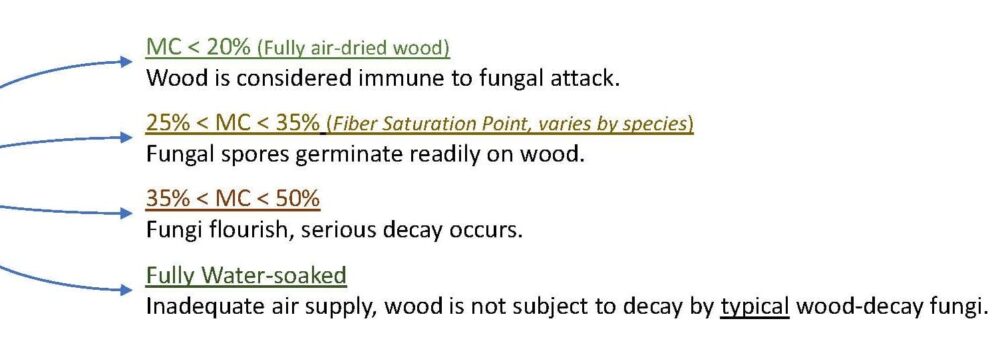

Moisture content is not as cut and dry (no pun intended) as some of the other conditions which promote fungal growth. Dry wood will not decay, period. When determining what causes wood rot, moisture content is key, since all wood-decaying fungi require “free water” to grow. Once water soaks into the wood until only water bound in the fiber cell walls remains, it has reached the fiber saturation point. “Free water” is the amount of water above the fiber saturation point. The wood fiber is unable to absorb more water. The percentage of moisture content needed to cause decay varies by wood species. Air-dried wood typically contains 18% water, which is below the fiber saturation level. Typically, wood is considered immune to fungal attack and rot when the moisture content is below 20%.

Depending on the wood species, the fiber saturation point is between 25-35%. Fungi will start to grow as soon as this point is reached. Once the moisture content reaches 35-50%, fungi will flourish, again depending on the wood species. The bad news is that fungi starts to grow as soon as there is enough moisture. The good news is that it will stop growing as soon as there is insufficient moisture and can pause for years.

-

Oxygen

The presence of oxygen is an unsurprising component, since most living organisms need it to survive. This means that a log completely soaked in water won’t have air for the fungi and the wood will not decay. The fungi will suffocate by carbon dioxide with no interchange of air.

Broken Wooden Boards Image by SharieProductions via Flickr

-

Temperature

The last component for wood to rot is a temperature that encourages fungal growth. This is a wide range of 65 to 95 degrees fahrenheit. There is a slight difference depending on the species of wood, as well. When the temperature is much higher or lower than this range, fungi growth will slow down. Above 100 degrees or at freezing temperatures, fungi will make very little progress or cease altogether.

When all five ingredients orcomponents are present, wood is bound to rot. Often some of these components are already present in the wood or its surroundings. As soon as water enters the equation, the wood begins to decay. Keeping wood as dry as possible is the best way to ensure the integrity and quality of the product. It’s not always possible, especially in the Pacific Northwest, but there are also options for treating the wood beforehand.

Subscribe

We’ll send you a notification when a new story has been posted. It’s the easiest way to stay in the know.