Wood is, yet again, involved in an innovative product that University of Utah is designing and researching: the first Timber Buckling Restrained Brace (TBRB). These reduce bending, or restrain buckling as the name implies, but why?

Earthquake loads shake a building in all directions, predominantly laterally, or side-to-side. Builders aim to resist these lateral forces by means of shear walls, moment frames, diagonally braced frames, and more.

Buckling Restrained Braces (BRB) are one of the best new design elements for seismic design. Why are they so effective? They dissipate energy through the yielding of steel. BRBs look like a typical diagonally-braced steel frame; however, the diagonal section is where they differ.

With a conventional diagonally-braced frame, the diagonal piece is typically slender and used in tension. When the building sways one way, it puts this piece in tension. But when it sways the other way, the diagonal piece goes into compression and will buckle at a much lower load. Once it buckles it is not able to resist any more load.

With BRB, the compression phase resists the buckling and forces the steel to yield. Yielding is where the steel molecules dislocate and cause permanent deformation. This yielding is dissipating energy and is the key to a good design for seismic forces. It’s easy to make a strong and rigid system, but this causes high forces for all the other elements of the building and leads to substantial damage. We want to dampen the forces like a shock in a car and yielding is how this is accomplished.

Another benefit of BRBs is resiliency. These diagonal pieces can be opened up and inspected after an earthquake. If required, they can be replaced. This is a huge advantage over many other types of lateral designs. Many buildings will survive an earthquake, but have to be torn down afterward.

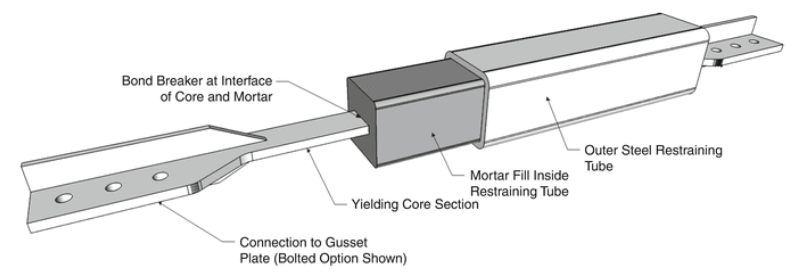

Typically, BRBs resist compression by encasing the diagonal steel plate in a concrete-filled, rectangular steel tube. However, the concrete is released from the steel plate so it can move freely and be stressed independently. The plate is supported by the concrete and buckling is restrained.

With the TBRB, our Mass Ply Panel is used to replace the mortar-filled rectangular steel tube. This creates a more sustainable, lightweight and aesthetically pleasing option. Plus, it will be an open-source design, allowing design and manufacturing in the open market versus the proprietary counterparts.

Testing from the University of Utah shows that TBRB meets the AISC standards for BRBs. This report is for the first phase of testing which is for the beam-column connections only. Testing of TBRB is still under review and should be published soon.

Mass timber buildings are already the desirable option for earthquake regions due to their lightweight nature, and thus less force generated. However, there aren’t many examples of mass timber lateral resistant systems out there. They are being tested and show huge promise.

The BRB frame is another option for designers and building owners seeking more sustainable designs, a beautiful architectural element, and resiliency and safety in an earthquake.

A special thank you to Chris Pantelides and Emily Diedrich, both from the University of Utah, for their work on designing and testing the BRBs.

Subscribe

We’ll send you a notification when a new story has been posted. It’s the easiest way to stay in the know.